Volume Room I: 800 l Room II: 12 l Room III: 5 l

Material: 1.4571

Min / Max allowed temperature: -20 / +200 °C

Max allowed pressure Room I: +6 / -1 bar

Room II + Room III +18 / -1 bar

Author: Gruber

Test equipment Mock Up

Volume: 9800 l

Max allowed pressure: atm

Min / Max allowed temperature: 50 °C

Agitator vessel 20 m³

Volume Room I: 20.000 l Room II: 960 l

Material: 1.4571

Min / Max allowed temperature: -10 / +200 °C

Max allowed pressure: +6 / -1 bar

Acid washing tower

Volume: 50.700 l

Material: 1.4539

Max allowed pressure: +3 / -1 bar

Min / Max allowed temperature: -20 / 250 °C

Vertical bulk dryers

Material: 1.4541

Volume vessel: 5.485 l Heating: 200 l

Max allowed pressure vessel: -1 / +1,5 bar Heating: -1 / +8 bar

Min / Max allowed temperature: -10 / +185 °C

Transport vessel 800 l

Volume Room I: 810 l Room II: 180 l

Material Room I: 2.4602 Room II: 1.4571

Min / Max allowed temperature: -60 / +200 °C

Max allowed pressure: +6 / -1 bar

Crystallizer

Volume Room I: 1.700 l Room II: 170 l

Material Room I: 1.4404 Room II: 1.4571

Min / Max allowed temperature: -10 / +200 °C

Max allowed pressure: +6 / -1 bar

Expansion vessel

Volume: 1.000 l

Material: S235JRG2

Min / Max allowed temperature: +5 / +45 °C

Max allowed pressure: +0,1 bar

Storage vessel 32 m³

Volume: 34.350 l

Material: 1.4571

Min / Max allowed temperature: -10 / +50 °C

Max allowed pressure: 3,2 bar

Reactor

Volume Room I: 8.000 l

Room II: 145 l

Material: 1.4571

Min / Max allowable temperature: +20 / +200 °C

Max allowable pressure Room I: +6 / -1 bar

Room II: +10 / -1 bar

Wax intermediate vessel

Volume Room I: 7800 l

Room II: 245 l

Room III: 170 l

Material: 1.4571/1.4539

Max allowed temperature: 200 °C

Max allowed pressure: +6 / -1 bar

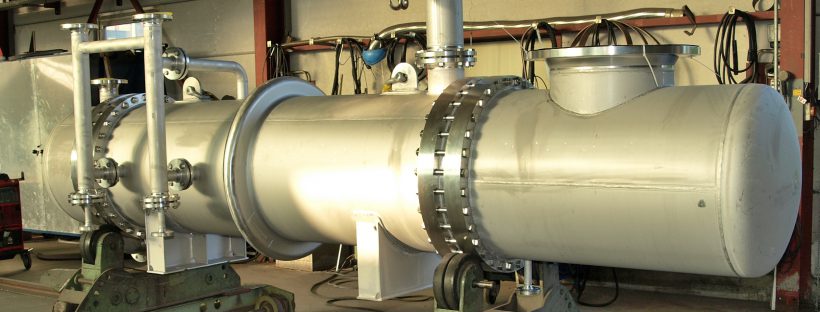

Heat exchanger DN750x2500

Volume Room I: 1065 l

Room II: 670 l

Material: 1.4571

Min / Max allowed temperature: -25 / +350 °C

Max allowed pressure: +6 / -1 bar

Roof cap for septic tank

Werkstoff: 1.4301